Anti-Slip Additives

Anti-Slip Additives

Couldn't load pickup availability

Antel's anti-slip additives enhance safety and aesthetics by offering a range of slip-resistant solutions, including durable non-slip aggregates for high-traction surfaces and subtle anti-slip beads for maintaining visual appeal, all customisable to achieve the desired level of slip resistance.

More Information

More Information

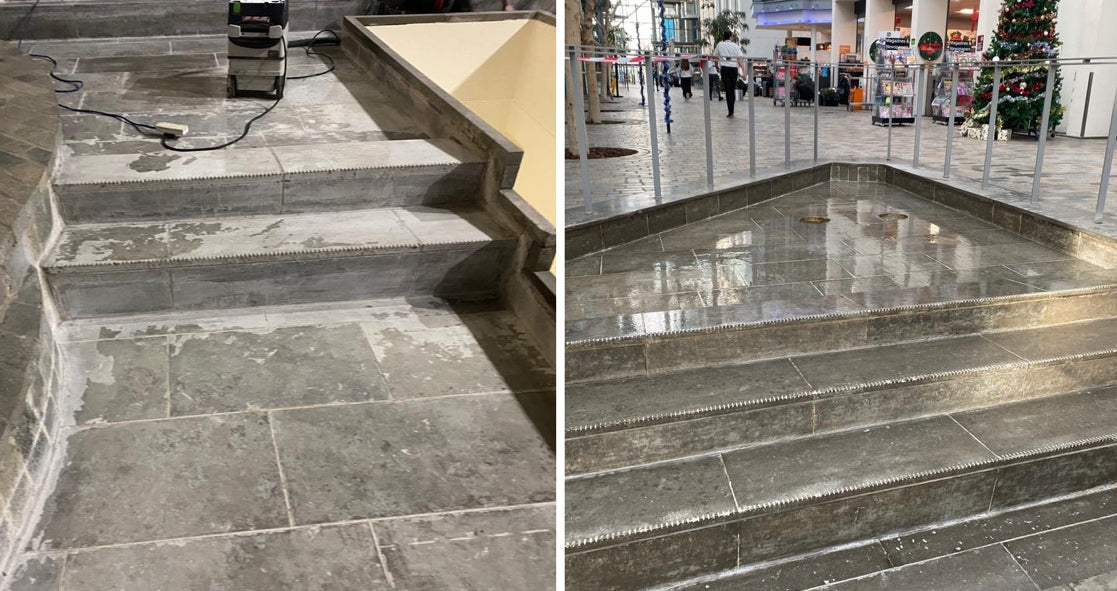

Variety of anti-slip aggregate & bead for use with Antel's epoxy coatings. Our Anti-Slip Bead can be used as an additive for applications that require a mild to medium level of anti-slip while our Non-Slip Aggregate can be used for a more aggressive anti-slip finish or where more control over the final finish is required.

Can be mixed into a variety of Antel epoxy products including Epoxy ClearCoat Resin, PoolCoating System 10, Epoxy Coating & Epoxy Coating Heavy Duty.

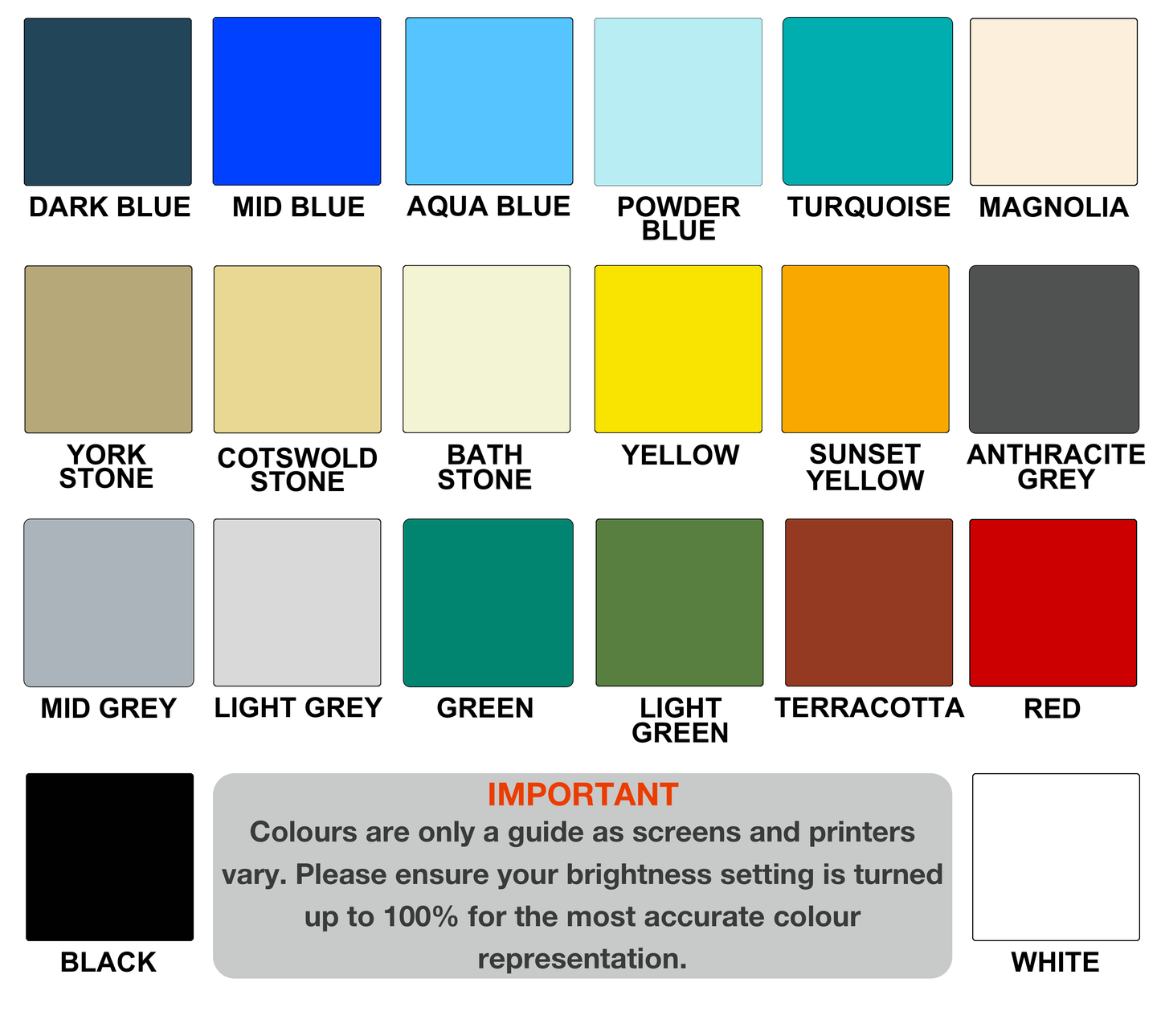

Non-Slip Aggregates:

Available in Fine, Medium, and Coarse grades.

Grade selection depends on the intended use and desired level of slip resistance.

Anti-Slip Bead:

Available in Standard (250-425 micron) and Coarse (425-850 micron) grades.

Provides a subtle, non-slip surface.

Suitable for applications such as coping stones, swimming pool steps, and factory floors.

How to Use

How to Use

APPLICATION

Non slip aggregates are applied in the same way for all systems.

Firstly a single application of the coating is applied to a carefully prepared surface. While this is still wet and active the non-slip aggregate is ‘broadcast’ evenly over the surface.

Do not over apply the aggregate as this is counter productive and will leave a surface which is very difficult to clean.

Allow the first coat to become tack free. Use a vacuum cleaner to remove any excess aggregate that has not adhered to the first coat.

Apply a further coat to the vacuumed area in order to lock in the non slip aggregate. A third coat may be required if the cover over the first coat and aggregate leaves a too harsh surface.

Preparation is of vital importance. Lighter application result in optimum performance.

Clear Anti-Slip Bead

Anti-Slip Bead is easy to apply and provides a subtle non- slip surface ideal for a variety of applications. Available in two grades; standard (250-425 micron) and coarse (425- 850 micron) Anti-Slip Bead is a great way to maintain the aesthetics of the substrate or coating.

USAGE EXAMPLES

- Coping stones.

- Swimming pool steps

- Factory floors

Can be mixed into a variety of Antel epoxy products including Epoxy ClearCoat Resin, PoolCoating System 10, Epoxy Coating & Epoxy Coating Heavy Duty.

COVERAGE

One pot of Anti-Slip Bead is enough for 1kg of material if a moderate level of anti-slip is required. Adjust the amount used depending on the level of slip resistance required.

APPLICATION

Simply pour the Anti-Slip Bead into the epoxy coating and mix thoroughly before applying the product in the usual way.

NOTE

Aggregate and anti-slip bead can vary and application technique will impact the level of anti-slip, therefore the grades are a guide only and Antel cannot be held responsible for the anti-slip performance.

Technical Information

Technical Information

Delivery

Delivery

Speedy delivery is our promise! Expect your order to arrive promptly, typically between 24-48 hours, thanks to our efficient service.

Trusted by Our Customers

3 Steps to perfect application

-

☑️ Finalise your choice

Choose the appropriate size and colour for your project. Need help choosing? Our friendly team are here to help - contact us!

-

☑️ Order your chosen product

Once you've finalised your order head to the checkout to complete your purchase. Your order will be dispatched within 24-48 hours.

-

☑️ Apply your product with ease

Our easy-to-use formulas make application a breeze. Follow the manufacturer's instructions for a flawless finish.

Why choose Antel for your flooring products?

At Antel, we're your one-stop shop for all your building chemical needs. Here's why you should choose us:

-

🌟 Unmatched expertise

We have over 20 years of experience in formulating and manufacturing high-performance building chemicals.

-

👍 Superior products

Our floor paints,anti-slip adhesives, andfloor screedsare designed for easy application, long-lasting durability, and a minimal environmental footprint.

-

🚀 Fast delivery

Get your project started quickly! Most orders are dispatched within 24-48 hours for fast delivery within the UK

★★★★★ Next Level Flooring

British Airways Hangar

Used this heavy-duty paint at the British Airways hangar—excellent coverage, tough finish, and built to withstand heavy use. Perfect for industrial environments. Highly recommended.

★★★★★ Mr Ian R

Very happy!

I am very happy… the small stones are now bonded together, and another coat would be too much as I would loose the grip on the patio that the children play on. Thanks for your help and advice on selecting the right product.

★★★★★ Mr John S

Extremely pleased

The instructions from Julian and recommendations in regards to tools and laying the flooring were invaluable and enabled me to achieve a showroom like finish which i am extremely pleased with.

★★★★★ Mr Ross J

Looks great

Just wanted to say thanks for helping me out with the resin products, it was the perfect quantity and looks great.

Fast Set Solvent-Free Epoxy Coating Applied to The Shard’s Stairway for Rapid Refurbishment

Heavy-Duty Epoxy Coating Revitalises the Floor of Marwell Zoo’s Tropical House

Antel Epoxy Resin Enhances the Refurbishment of Gunwharf Linkspan Bridge

Antel Self-Smoothing Floor Screed and Epoxy Coating Applied in The Fisheries, London

Antel Epoxy ClearCoat Resin Enhances British Airways Lounge Refurbishment at Heathrow

Antel Water-Based Epoxy Floor Paint Applied at London Cakes

FAQs

What makes Antel's flooring products different?

Our products are formulated with over 20 years of experience for superior ease of use, long-lasting durability, and minimal environmental impact.

How do I choose the right flooring solution for my project?

We offer a wide selection! Our dedicated technical team is happy to answer your questions and help you find the perfect product for your specific needs. Feel free to contact us!

How fast can I get my order?

Most orders are dispatched within 24-48 hours for fast delivery within the UK (additional charges may apply). We also handle international shipping!

Can I still get help if I'm unsure during my project?

Absolutely! Our technical support team is always happy to offer guidance on proper application to ensure flawless results.

Are Antel's products environmentally friendly?

Yes! We take environmental responsibility seriously and strive to create high-performance products with minimal environmental impact.

Need some expert advice?

Our knowledgeable support team is here for you! Whether you have questions about a specific product or need help choosing the right one, we're happy to assist.