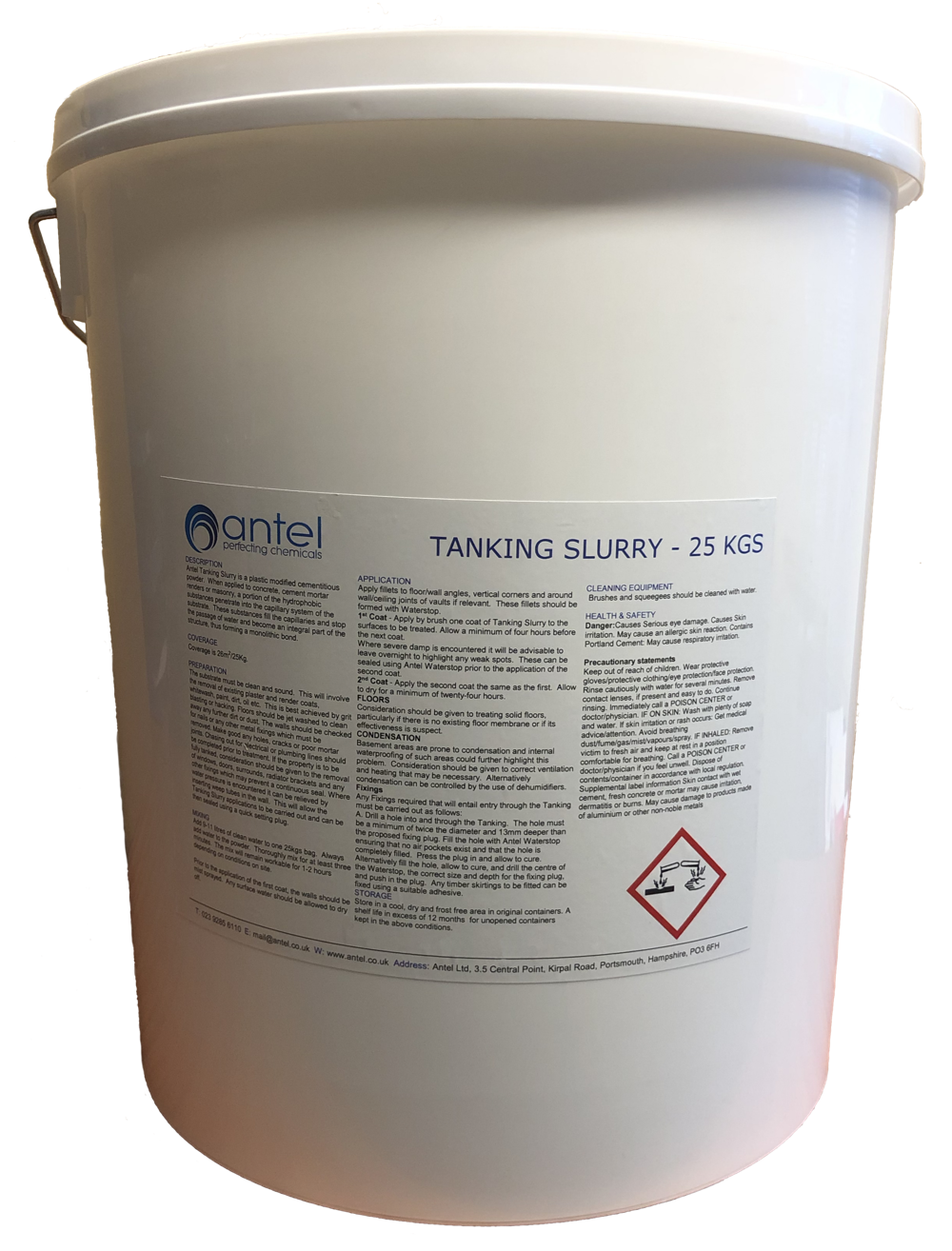

Tanking Slurry

Tanking Slurry

Couldn't load pickup availability

Antel Tanking Slurry is designed to protect against water penetration on various surfaces.

✅ Can be applied to concrete, blockwork masonry, and cement renders.

✅ Suitable for both old and new surfaces, ensuring a strong waterproof barrier.

✅ Forms a monolithic bond, filling capillaries to prevent water ingress.

More Information

More Information

Antel Tanking Slurry is a ready-mixed, plastic-modified, and hydraulically setting powder ideally suited to basement tanking. When applied to concrete, cement mortar renders, or masonry, a portion of the hydrophobic substances penetrate into the capillary system of the substrate. These substances fill the capillaries and stop the passage of water, becoming an integral part of the structure and forming a monolithic bond.

Tanking Slurry can be used in a wide range of areas, for commercial and domestic properties, as well as in building, basement tanking, cellar tanking, construction, and civil engineering projects. It may be applied to the positive and negative sides of a structure against pressure water, ground moisture, and dampness. It can be used to waterproof both old and new structures, internally and externally. It bridges hairline cracks, resists the freeze/thaw cycle, is non-toxic, non-corrosive, prevents efflorescence, and is resistant to chemicals.

- Packaging: 25kg per bag.

- Tanking Slurry Coverage: 2kg of mixed material per 1 square metre.

- Storage: Store in cool, dry, frost-free conditions in original containers. Protect from freezing. Keep out of reach of children.

How to Use

How to Use

SURFACE PREPARATION

The substrate must be clean and sound. This will involve the removal of existing plaster and render coats, whitewash, paint, dirt, oil etc. This is best achieved by grit blasting or hacking depending on how clean the substrate is. Once clean and sound, the floors should be jet washed to clean away any further dirt or dust.

The walls should be checked for nails or any other metal fixings which must be removed.

Make good any holes, cracks or poor mortar joints using Antel Waterstop or mortar with Antel Rendermix additive.

Chasing out for electrical or plumbing lines should be completed prior to treatment.

If the property is to be fully tanked, consideration should be given to the removal of windows, doors, surrounds, radiator brackets and any other fixings which may prevent a continuous seal. Any pipe intrusions should be chased out to 25mm around and 25mm deep and made good.

Where water pressure is encountered it can be relieved by inserting weep tubes in the wall. This will allow the Tanking applications to be carried out and can be subsequently sealed using a quick setting plug.

Where severe water seepage is experienced or where the angle is found to be suspect, chase out to a minimum of 25 mm from the wall and 25mm into the floor, cutting into the wall where possible.

MIXING/APPLICATION

Add 7-9 litres of solution (water or water/SBR combination) to one 25kgs bag. If using Antel SBR we recommend using a mix of 3 parts water to 1 part SBR. The addition of SBR will enhance the waterproofing properties, flexibility and adhesion and is highly recommended. Thoroughly mix for at least three minutes. The mix will remain workable for 1-2 hours depending on conditions on site.

Prior to the application of the first coat, the walls should be mist sprayed. Any surface water should be allowed to dry off. Apply fillets to floor/wall angles, vertical corners and around wall/ceiling joints of vaults if relevant. These fillets should be formed using Antel Waterstop.

1st Coat - Apply by brush one coat of Tanking Slurry to the surfaces to be treated. Allow a minimum of four hours before the next coat. Where severe damp is encountered it will be advisable to leave overnight to highlight any weak spots. These can be sealed using Antel Waterstop prior to the application of the second coat.

2nd Coat - Apply the second coat the same as the first. Allow to dry for a minimum of twenty-four hours. It will be beneficial to finish the first coat with vertical strokes and the second coat horizontally.

After the application of the second coat, you may want to apply a sand/cement render or a thermal renovating plaster. As an alternative, the tanking slurry can be left as the finish coat. If the Slurry is to be left as the finish coat it should not be decorated until complete cure and drying has occurred. Decoration should be confined to a non plastic emulsion paint. If conditions are damp with poor ventilation, full cure could take several months.

GENERAL NOTES

FLOORS

When a waterproofing contract is carried out consideration should be given to treating solid floors, particularly if there is no existing floor membrane or if its effectiveness is suspect.

By waterproofing the walls you may push the water elsewhere and it could reappear through a defective floor. If the floor is to be treated, any existing screed should be removed to allow the Tanking Slurry to be carried across the floor to form a continuous waterproof seal. This can be re-screeded or if there is sufficient headroom, Antel Self Levelling Floor Compound can be used. In all cases the slurry must be protected from wear.

CONDENSATION

Basement areas are prone to condensation and internal waterproofing of such areas could further highlight this problem. The application of Antel Rendermix in the cement mix or renovating plaster will reduce the problem but consideration should be given to correct ventilation and heating that may be necessary. Alternatively condensation can be controlled by the use of dehumidifiers.

Fixings

Any Fixings required that will entail entry through the Tanking must be carried out as follows:

A. Drill a hole into and through the Tanking. The hole must be a minimum of twice the diameter and 13mm deeper than the proposed fixing plug.

B. Fill the hole with Antel Waterstop ensuring that no air pockets exist and that the hole is completely filled. Press the plug in and allow to cure.

C. Alternatively after filling the hole, allow to cure, and drill in the centre of the cured Waterstop, the correct size and depth for the fixing plug, and push in the plug.

D. Any timber skirtings to be fitted can be fixed using a suitable adhesive.

Technical Information

Technical Information

Health & Safety: Tanking Slurry is non-combustible. Wear respiratory protection, gloves, and eye/face masks when mixing or handling. Do not inhale dust. Mix in a well-ventilated area. Refer to the full Health & Safety Data Sheet.

Floors: If waterproofing walls, consider treating solid floors to prevent water from resurfacing. If needed, remove existing screeds and extend the slurry across the floor for a continuous waterproof seal. Protect the slurry from wear by re-screeding or applying Antel Self-Levelling Floor Compound.

Condensation: Waterproofing basement areas can increase condensation. Adding Antel Rendermix to the cement mix or using a renovating plaster can help. Proper ventilation, heating, or dehumidifiers may also be necessary.

Fixings: Any fixings that penetrate the tanking must be carefully sealed using Antel Waterstop to maintain waterproof integrity. Drill a hole twice the diameter and deeper than the fixing plug, fill it with Antel Waterstop, and allow it to cure before inserting the fixing. Alternatively, after curing, drill the correct size hole for the plug and insert it securely.

Delivery

Delivery

Speedy delivery is our promise! Expect your order to arrive promptly, typically between 24-48 hours, thanks to our efficient service.

Trusted by Our Customers

3 Steps to perfect application

-

☑️ Finalise your choice

Identify the best product for your needs. Need help choosing? Our friendly team are here to help - contact us!

-

☑️ Order your chosen product

Once you've finalised your order head to the checkout to complete your purchase. Your order will be dispatched within 24-48 hours.

-

☑️ Apply your product with ease

Our easy-to-use formulas make application a breeze. Follow the manufacturer's instructions for a flawless finish.

Why Choose Antel for Superior Protection & Performance?

At Antel, we're your one-stop shop for all your building chemical needs. Here's why you should choose us:

-

🌟 Unmatched expertise

We have over 20 years of experience in formulating and manufacturing high-performance building chemicals.

-

👍 Superior products

Our solutions are designed for easy application, strong performance, lasting durability, and low environmental impact.

-

🚀 Fast delivery

Get your project started quickly! Most orders are dispatched within 24-48 hours for fast delivery within the UK

Dedicated support

Our technical team is always happy to offer advice and guidance on choosing the right product and ensuring proper application.

FAQs

What makes Antel’s Damp, Tanking, Repellents & Timber Treatments different?

With over 20 years of expertise, our products are designed for superior performance, ease of use, long-lasting protection, and minimal environmental impact.

How do I choose the right product for my project?

We offer a wide range of solutions for different applications! Our dedicated technical team is happy to answer your questions and assist you in selecting the perfect adhesive for your specific needs. Feel free to contact us!

How fast can I get my order?

Most orders are dispatched within 24-48 hours for fast delivery within the UK (additional charges may apply). We also handle international shipping!

Can I still get help if I'm unsure during my project?

Absolutely! Our technical support team is always happy to offer guidance on proper application to ensure flawless results.

Are Antel's products environmentally friendly?

Yes! We take environmental responsibility seriously and strive to create high-performance products with minimal environmental impact.

Need Help Choosing The Right Product?

Our technical team is here to assist! Whether you're unsure which solution is right for your project or have questions about using Antel products, we're happy to help. Feel free to contact us!