ClearCoat Epoxy Resin

ClearCoat Epoxy Resin

Couldn't load pickup availability

Antel ClearCoat Epoxy Floor Resin is a high-gloss, two-part epoxy coating that offers superior UV resistance minimising yellowing, provides exceptional durability and chemical resistance, and is compatible with most solvent-free paints.

More Information

More Information

Antel Clear Epoxy Resin Floor Paint is a clear, high gloss, two part epoxy coating with a high level of resistance to UV, substantially reducing the amount of yellowing that occurs when compared with other epoxy products. Epoxy ClearCoat Resin is very hardwearing, resistant to chemicals and compatible with most solvent free paint types.

USES

Antel Epoxy ClearCoat Resin can be used virtually anywhere that requires a clear, hard-wearing coating. Some of its popular uses are below:

- Penny floors

- Sealing bar tops and tables

- Decorative glossy finishes and effects

- Sealing polished concrete

PACKAGING

1kg & 3kg.

COVERAGE

This is highly dependent on the application thickness.

For an application thickness of 0.1mm, the estimated coverage is 10 m²/kg.

For an application thickness of 0.25mm, the estimated coverage is 4 m²/kg.

For an application thickness of 0.5mm, the estimated coverage is 2 m²/kg.

For an application thickness of 1mm, the estimated coverage is 1 m²/kg.

For an application thickness of 2mm, the estimated coverage is 0.5 m²/kg.

Multiple coats are required for thicknesses above 2mm.

How to Use

How to Use

5. PREPARATION

For surfaces that are already painted, make good the surface and then sand and clean the existing paint or coating to ensure a sound base. Particular attention should be made to degreasing surfaces before application.

Do not use any PVA coating on the substrate prior to application, as this will result in the paint peeling off.

All voids and surface imperfections must be carefully filled.

6. MIXING

If splitting packs into smaller quantities, this must be carried out accurately using digital scales.

Pour the entire contents of the smaller container, marked ‘B Pack’ into the larger container making sure to scrape out as much as possible.

Mix thoroughly, using a drill and paddle on a slow speed. Once combined, mix for a further 2-3 minutes on a slow speed to ensure complete uniformity.

Pour into at least two roller trays to maintain pot life and dissipate heat.

The coating is now ready to apply immediately to the prepared areas.

7. APPLICATION

Do not apply in temperatures below 10 °C.

The pot life for this coating is 45 minutes at 20°C. Warmer temperatures will reduce the pot life of the coating, which is why we recommend application takes place mid-morning when being used outdoors.

When being applied outdoors, ensure there is at least a day of dry weather before starting application.

Once mixed, it is only possible to apply a single coat. Do not attempt to return to the mix to apply a second coat.

Use a plum line when applying over a large area to ensure no spots are missed.

Apply using a foam roller, fine pile roller or notched trowel/squeegee depending on the desired application thickness

After applying, wait 3-7 days (depending on temperature) before heavy traffic.

8. DRYING & CURING

At 20 °C, and with reasonable ventilation, the coating is touch dry in 8 hours and hard dry in 12 hours. Maximum cure, hardness and chemical resistance is obtained within 7 days.

Technical Information

Technical Information

TECHNICAL DATA

Test Data @20°C

Pot life: 30 minutes

Application thickness: 200-225 µm per coat

Initial cure: 8 – 10 hours

Intercoat time: 24 hours

Pedestrian traffic: 24 hours

Heavy traffic: 36 hours

Full Cure: 7 days

Compressive Strength: 65 N/mm2

Flexural Strength: 26 N/mm2

Abrasion Resistance: 0.18 grams weight loss CS-17 wheel 1000 cycles 1 kg

STORAGE

Store in a cool, dry and frost free area in original containers. Protect from freezing. Keep out of the reach of children. A shelf life in excess of 12 months can be expected for unopened containers kept in the above conditions.

CLEANING EQUIPMENT

When using spray equipment a thorough rinsing with cold water every hour will prevent a buildup of cured material. Brushes and rollers should be washed with cold water and detergent and rinsed thoroughly in cold water.

Application equipment used to apply the 3rd Clear Sealer Coat should not be cleaned with water, but simply allowed to cure/harden and then disposed of.

HEALTH & SAFETY

Antel Epoxy ClearCoat Resin is much safer to handle than other resin systems; however, it is recommended that all skin contact is avoided and that if contact is made, are washed immediately with soap and warm water. It is advisable to use a barrier cream and gloves when applying.

FOR FULL DETAILS PLEASE REFER TO HEALTH & SAFETY DATA SHEET.

A Note from Antel

We make every attempt to provide as much information as possible on the mixing and application of Antel’s Epoxy ClearCoat Resin, however, if there is something you are not sure of, or if you have a particular request or problem, please don’t hesitate to contact us and we will only be too happy to help. Antel is committed to providing a superior before and after sales service.

Delivery

Delivery

Speedy delivery is our promise! Expect your order to arrive promptly, typically between 24-48 hours, thanks to our efficient service.

Trusted by Our Customers

3 Steps to perfect application

-

☑️ Finalise your choice

Choose the appropriate size and colour for your project. Need help choosing? Our friendly team are here to help - contact us!

-

☑️ Order your chosen product

Once you've finalised your order head to the checkout to complete your purchase. Your order will be dispatched within 24-48 hours.

-

☑️ Apply your product with ease

Our easy-to-use formulas make application a breeze. Follow the manufacturer's instructions for a flawless finish.

Why choose Antel for your flooring products?

At Antel, we're your one-stop shop for all your building chemical needs. Here's why you should choose us:

-

🌟 Unmatched expertise

We have over 20 years of experience in formulating and manufacturing high-performance building chemicals.

-

👍 Superior products

Our floor paints,anti-slip adhesives, andfloor screedsare designed for easy application, long-lasting durability, and a minimal environmental footprint.

-

🚀 Fast delivery

Get your project started quickly! Most orders are dispatched within 24-48 hours for fast delivery within the UK

★★★★★ Next Level Flooring

British Airways Hangar

Used this heavy-duty paint at the British Airways hangar—excellent coverage, tough finish, and built to withstand heavy use. Perfect for industrial environments. Highly recommended.

★★★★★ Mr Ian R

Very happy!

I am very happy… the small stones are now bonded together, and another coat would be too much as I would loose the grip on the patio that the children play on. Thanks for your help and advice on selecting the right product.

★★★★★ Mr John S

Extremely pleased

The instructions from Julian and recommendations in regards to tools and laying the flooring were invaluable and enabled me to achieve a showroom like finish which i am extremely pleased with.

★★★★★ Mr Ross J

Looks great

Just wanted to say thanks for helping me out with the resin products, it was the perfect quantity and looks great.

Fast Set Solvent-Free Epoxy Coating Applied to The Shard’s Stairway for Rapid Refurbishment

Heavy-Duty Epoxy Coating Revitalises the Floor of Marwell Zoo’s Tropical House

Antel Epoxy Resin Enhances the Refurbishment of Gunwharf Linkspan Bridge

Antel Self-Smoothing Floor Screed and Epoxy Coating Applied in The Fisheries, London

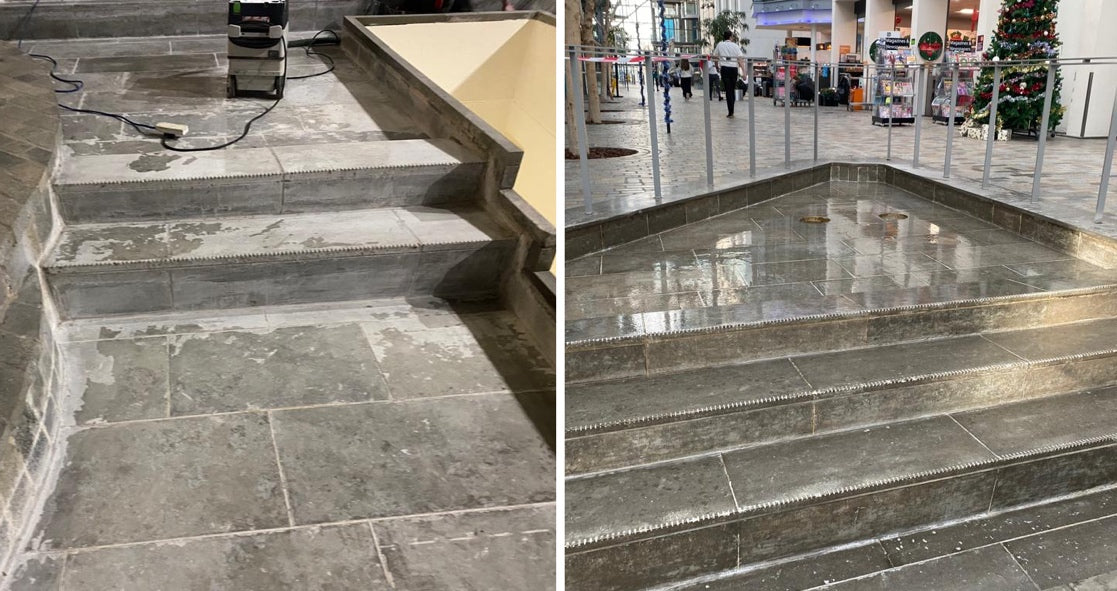

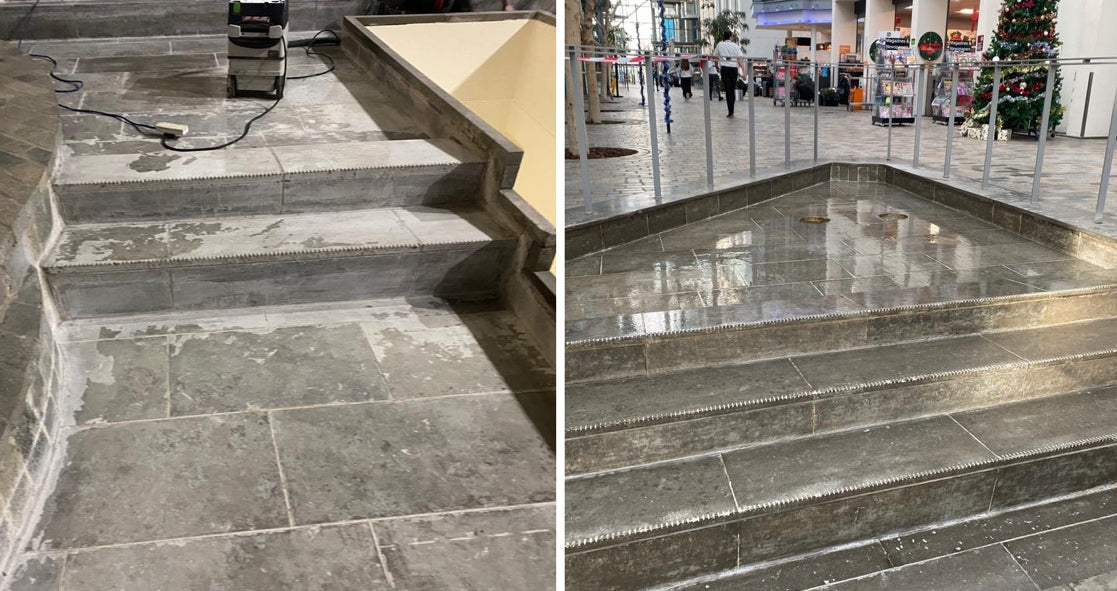

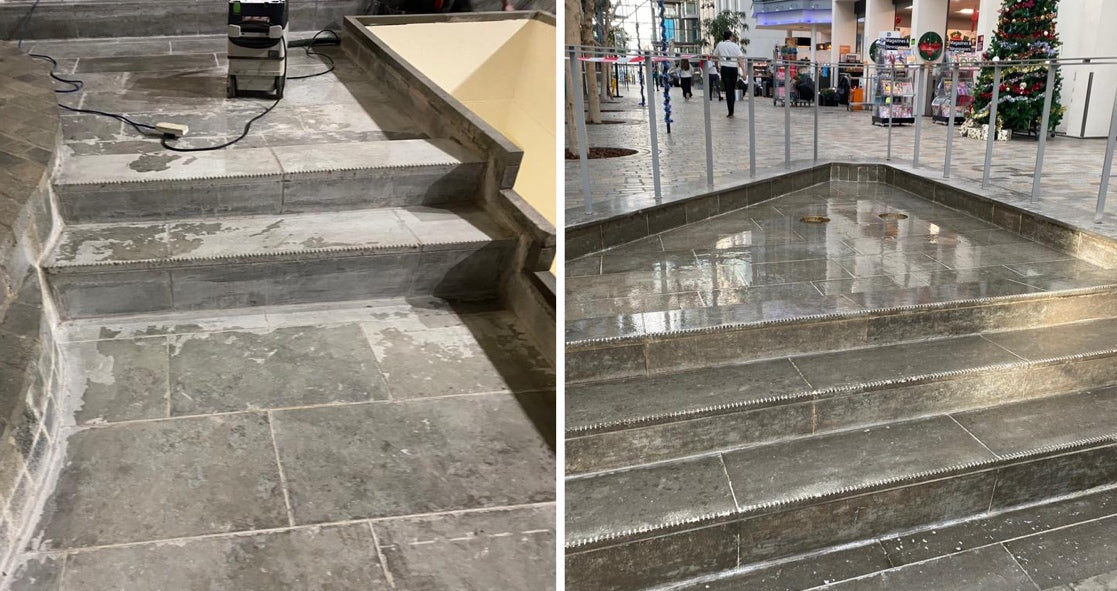

Antel Epoxy ClearCoat Resin Enhances British Airways Lounge Refurbishment at Heathrow

Antel Water-Based Epoxy Floor Paint Applied at London Cakes

FAQs

What makes Antel's flooring products different?

Our products are formulated with over 20 years of experience for superior ease of use, long-lasting durability, and minimal environmental impact.

How do I choose the right flooring solution for my project?

We offer a wide selection! Our dedicated technical team is happy to answer your questions and help you find the perfect product for your specific needs. Feel free to contact us!

How fast can I get my order?

Most orders are dispatched within 24-48 hours for fast delivery within the UK (additional charges may apply). We also handle international shipping!

Can I still get help if I'm unsure during my project?

Absolutely! Our technical support team is always happy to offer guidance on proper application to ensure flawless results.

Are Antel's products environmentally friendly?

Yes! We take environmental responsibility seriously and strive to create high-performance products with minimal environmental impact.

Need some expert advice?

Our knowledgeable support team is here for you! Whether you have questions about a specific product or need help choosing the right one, we're happy to assist.