Antel

Feed Passage Epoxy Coating

Feed Passage Epoxy Coating

Couldn't load pickup availability

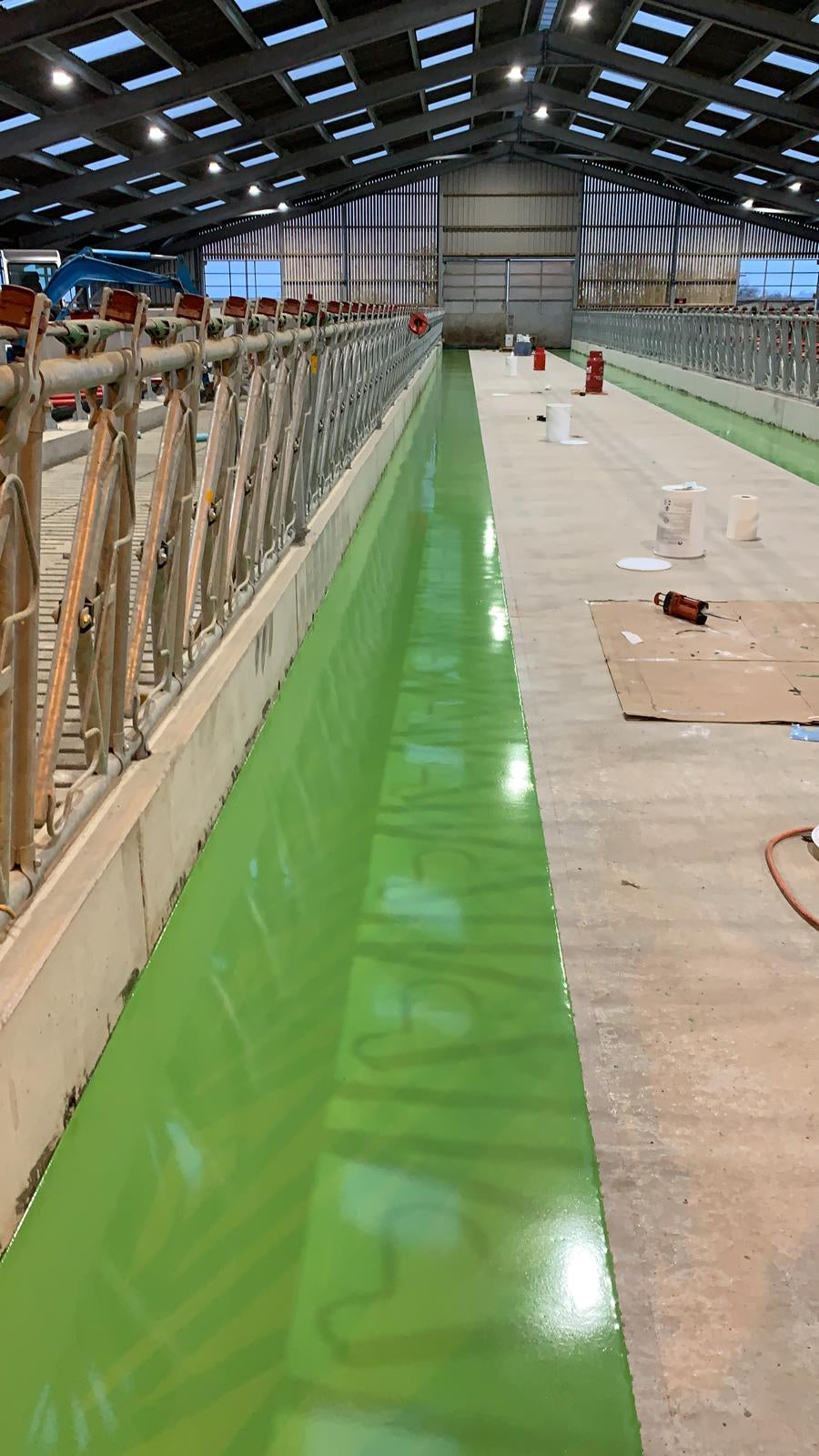

Antel Feed Passage Epoxy Coating has been developed for agricultural feed passages that require a smooth finish that's very hard-wearing. By using the most up to date in solvent free technology Antel Feed Passage Epoxy Coating will produce an easily cleaned, non toxic, chemically resistant floor with good colour and colour retention.

Technical Data

Antel Epoxy Primer is required in the application of this product. We also recommend Antel Epoxy Cleaning Solvent to clean any tools used during application.

Feed Passage Epoxy Coating

1. DESCRIPTION

Antel Feed Passage Epoxy Coating has been developed for agricultural feed passages that require a smooth finish that's very hard-wearing. By using the most up to date in solvent free technology Antel Feed Passage Epoxy Coating will produce an easily cleaned, non toxic, chemically resistant floor with good colour and colour retention.

2. PACKAGING

Three pack system consisting of “A1”, "A2", “B” and “C”, aggregate, resin and hardener. Supplied in 25kg packs.

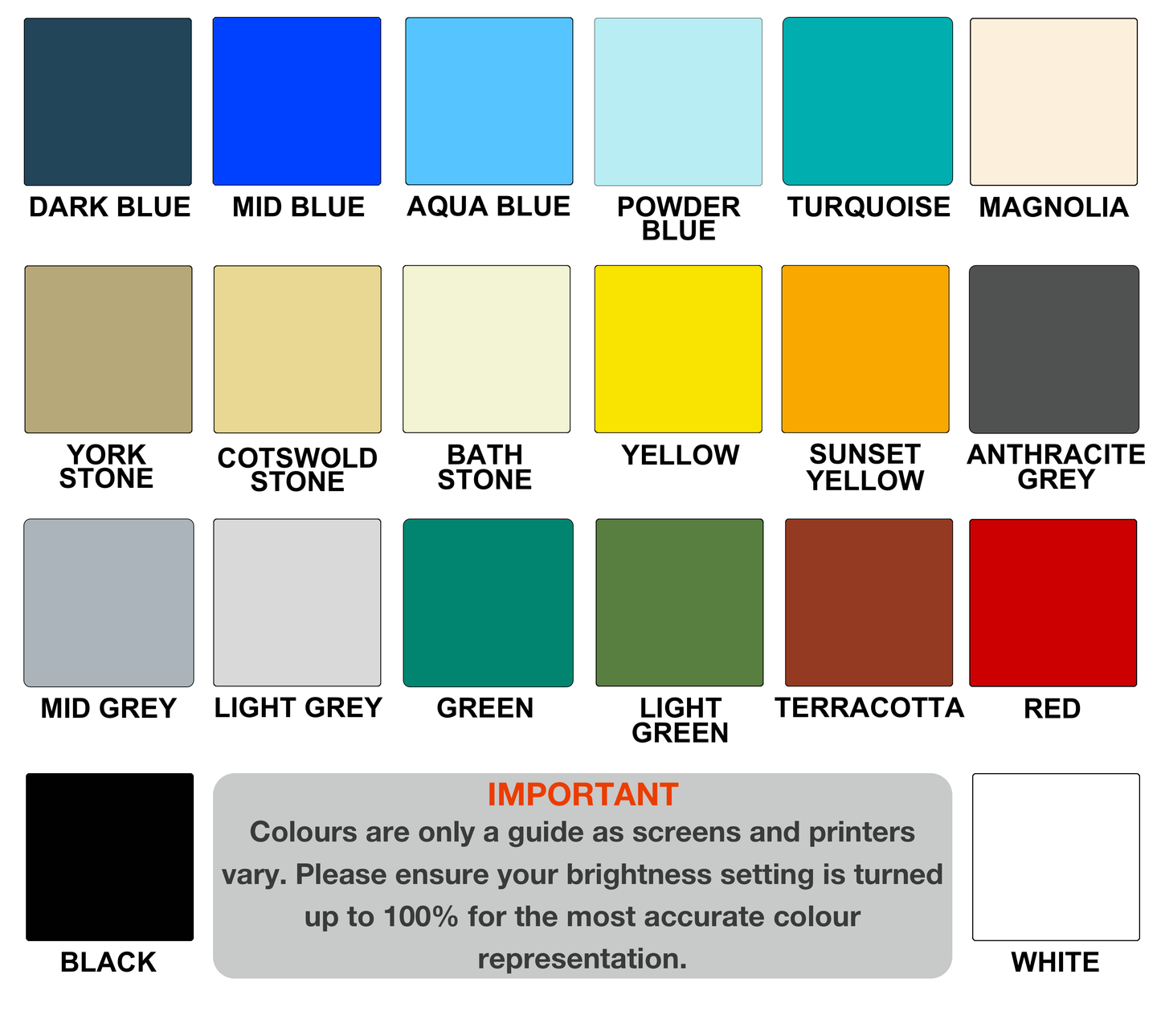

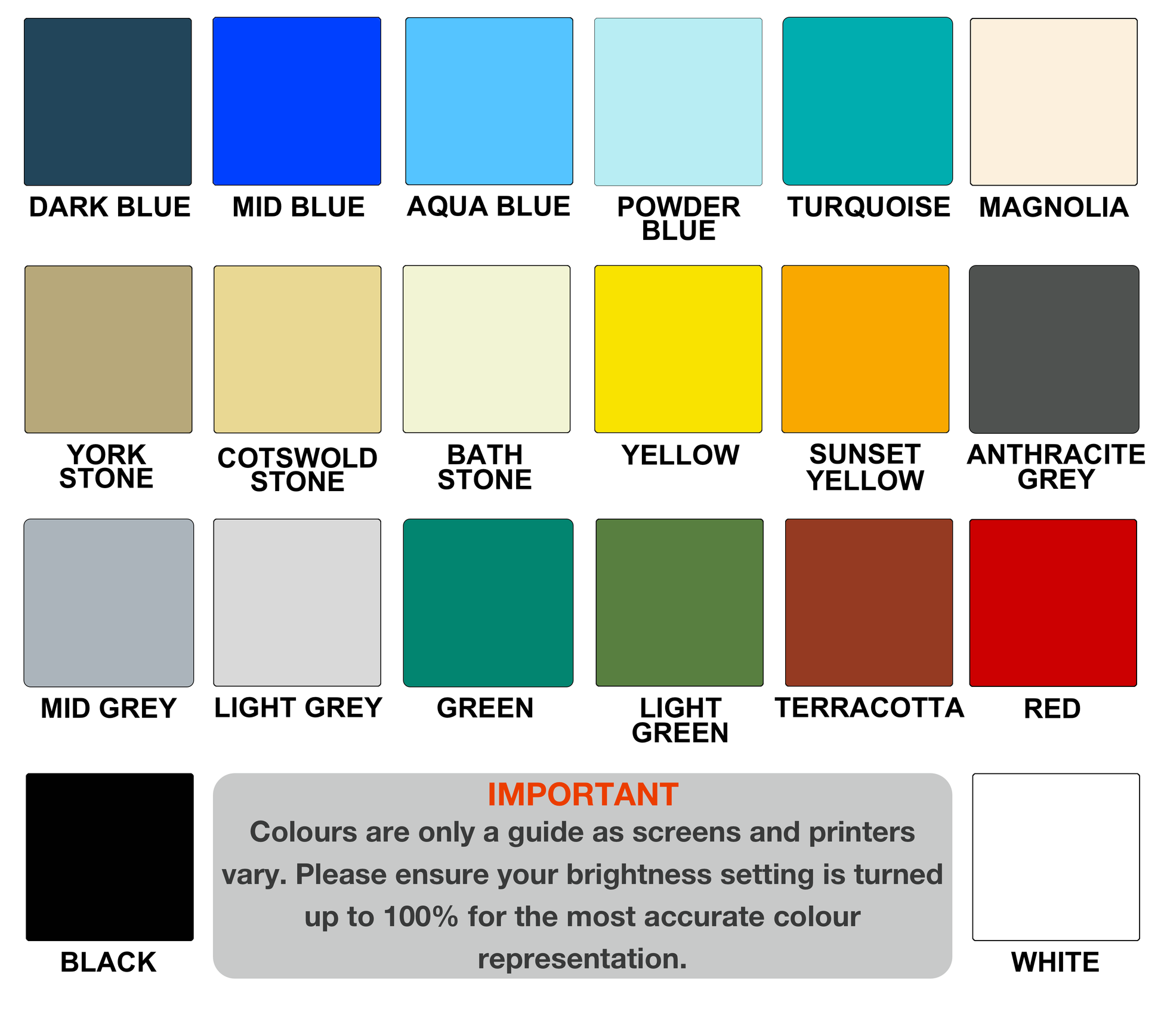

3. COLOUR

A variety of colours are available including green, blue, red and grey. Please see the website for our full range. Specific colours can be produced upon special request.

Note: When ordering quantities over 5, your order will be custom made for you, therefore we won't be able to accept returns because of a change of mind.

4. USAGE RATE

At 2 mm thickness a 25 Kg will cover 6-7 m².

5. SHELF LIFE

12 months in sealed containers.

6. INSTRUCTIONS FOR USE

6.1 Preparation:

Surfaces must be dry and free from all foreign matter such as dust, grease and dirt etc. Weak laitance and loose or flaking material must be removed by ‘grit’ blasting or at the very least wire brushing. Best results can be obtained by the use of the appropriate Antel cleaner.

Due to the porosity of substrates having an effect on the structure of self smoothing systems, it is important to apply a primer to the substrate in order to seal it. Antel’s Self Smoothing Floor Screed Primer has been especially developed for this purpose.

6.2 Mixing:

Stir the B Pack. Empty the entire contents of A Pack 1, A Pack 2 & B Pack into the bucket (as supplied) and mix with drill and paddle for 3 minutes on a slow speed. Slowly add powder C Pack while mixing continuously. Finally, stir for a further 3 minutes on a slow speed to obtain a smooth free flowing mix. Pour immediately. Do not allow the aggregate to settle before pouring.

6.3 Application:

Once mixed Antel Self-Smoothing Floor Screed can generate a lot of heat. Storing the material in a cool place and applying in cooler conditions will reduce the amount of heat generated and result in the best possible finish.

Having allowed the previously applied Antel Self Smoothing Floor Primer to cure, pour the compound on to the substrate and spread out using a squeegee/float before using a ‘spiked’ roller, which not only aids movement of the compound but aids de-aeration also. Apply at a thickness of 2 mm.

IMPORTANT - We strongly recommend wearing spiked shoes so that a spiked roller can be used across the entire area while still wet. Failure to do this may result in a subpar finish.

6.4 Curing:

Pot life 160g mix @ 25°C = 25 minutes

Thin film set time @ 25°C = 7 hours

@ 10°C = 23 hours

Full cure schedule 2 - 7 days at ambient temperature.

6.5 Overcoating:

Further protection can be obtained by using one of a selection of Antel floor paints.

6.6 Cleaning tools:

Immediately after use, tools should be cleaned with Antel cleaning solvent.

7. TYPICAL PERFORMANCE PROPERTIES

After 7 day cure @ 25°C

Flexural strength, Mpa -40

Flexural Modulas, Gpa -6

*Chemical resistance (data available) -very good

Water spotting resistance -excellent

Colour stability - long term

* NOTE: Chemical resistance is specific, therefore seek advice