Dairy Coat Ultra Antibacterial

Dairy Coat Ultra Antibacterial

Couldn't load pickup availability

Note: Epoxy Bagging Coat can be used in conjunction with Dairy Coat Ultra. Click here for more information.

-

Dairy Coat Ant-Bac has been further enhanced by the addition of a highly effective anti-microbial agent that has a 99.999% kill rate against E. Coli and MRSA.

-

The additive contained will not leach and has no environmental impact.

-

It is effectiveness is unaffected by:

-

Scratching or abrasion

-

UV exposure

-

Salt Spay

-

Temperature cycling

-

Cleaning chemicals including Chlorine Bleach, Disinfectants, Quaternary Ammonium Compounds.

-

-

Effective for the life time of the coating.

-

The active ingredient is effective against most bacteria including Listeria, Monocytogenes, Salmonella Enteritidis, Pseudomonas Aeruginosa and Aspergillus, Niger and specifically tested against MRSA and E. Coli.

-

No document evidence that bacteria strains have become resistant.

Technical Data

Dairy Coat Ultra Technical Data Sheet

1. DESCRIPTION

Antel's Dairy Coat Ultra is a high quality high build two component solvent free epoxy coating for application to new and existing concrete floors, render, and metal substrates. It provides a smooth, easily cleaned surface which is resistant to dirt, moisture, oil, light-medium abrasion and chemical attack. Where slip resistance is required, and in accordance with BS 7976-2, the addition of Anti-Slip aggregate is required in most cases.

2. FEATURES, BENEFITS

• High build—200 µm per coat

• Superb adhesion to concrete

• Good early strength characteristics

• Dustproof and waterproof

• Good chemical resistance.

• Impermeable to water and other liquids.

• Good resistance to heavy traffic

• Provides a closed hygienic surface

• Can be made non-slip

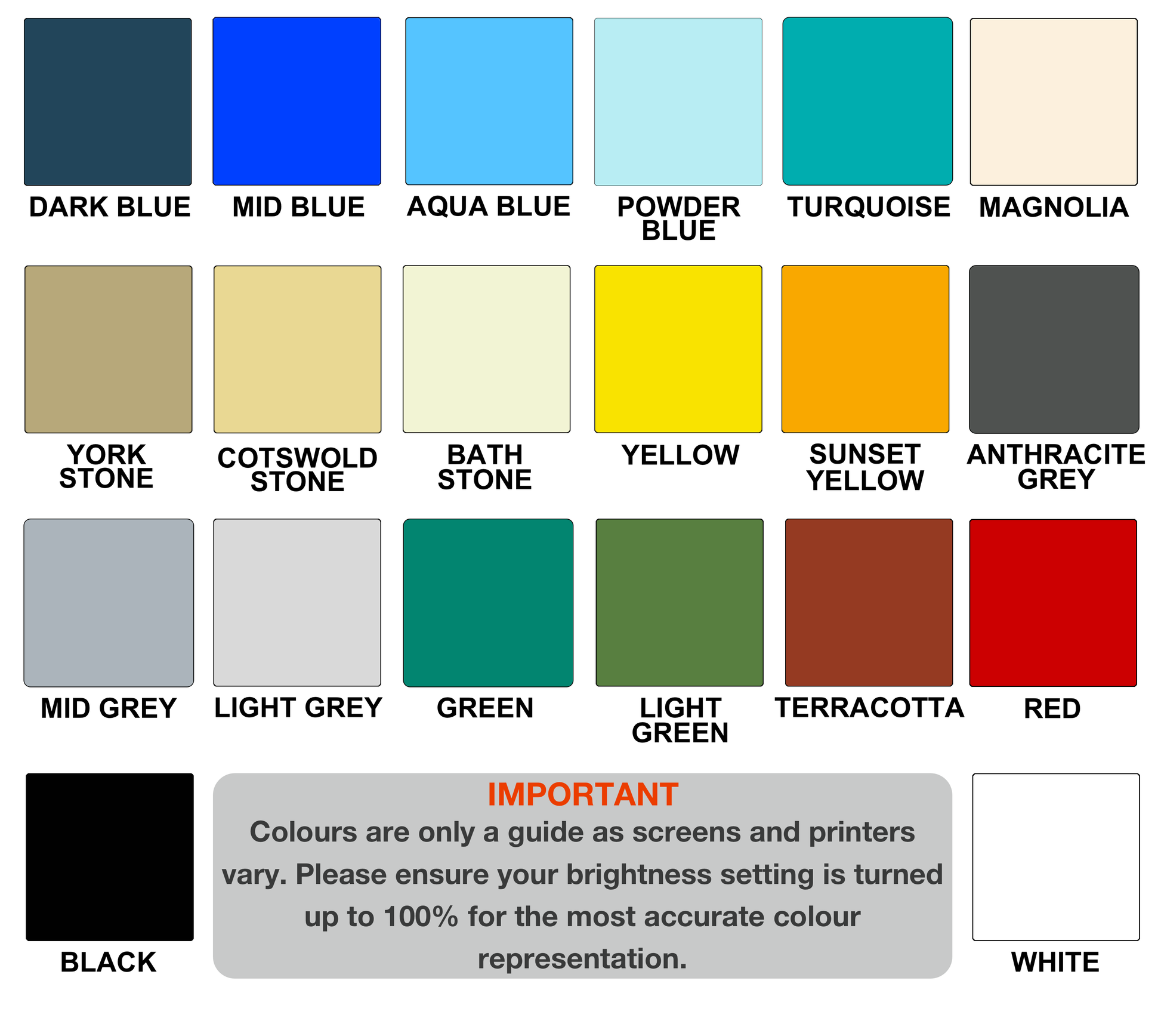

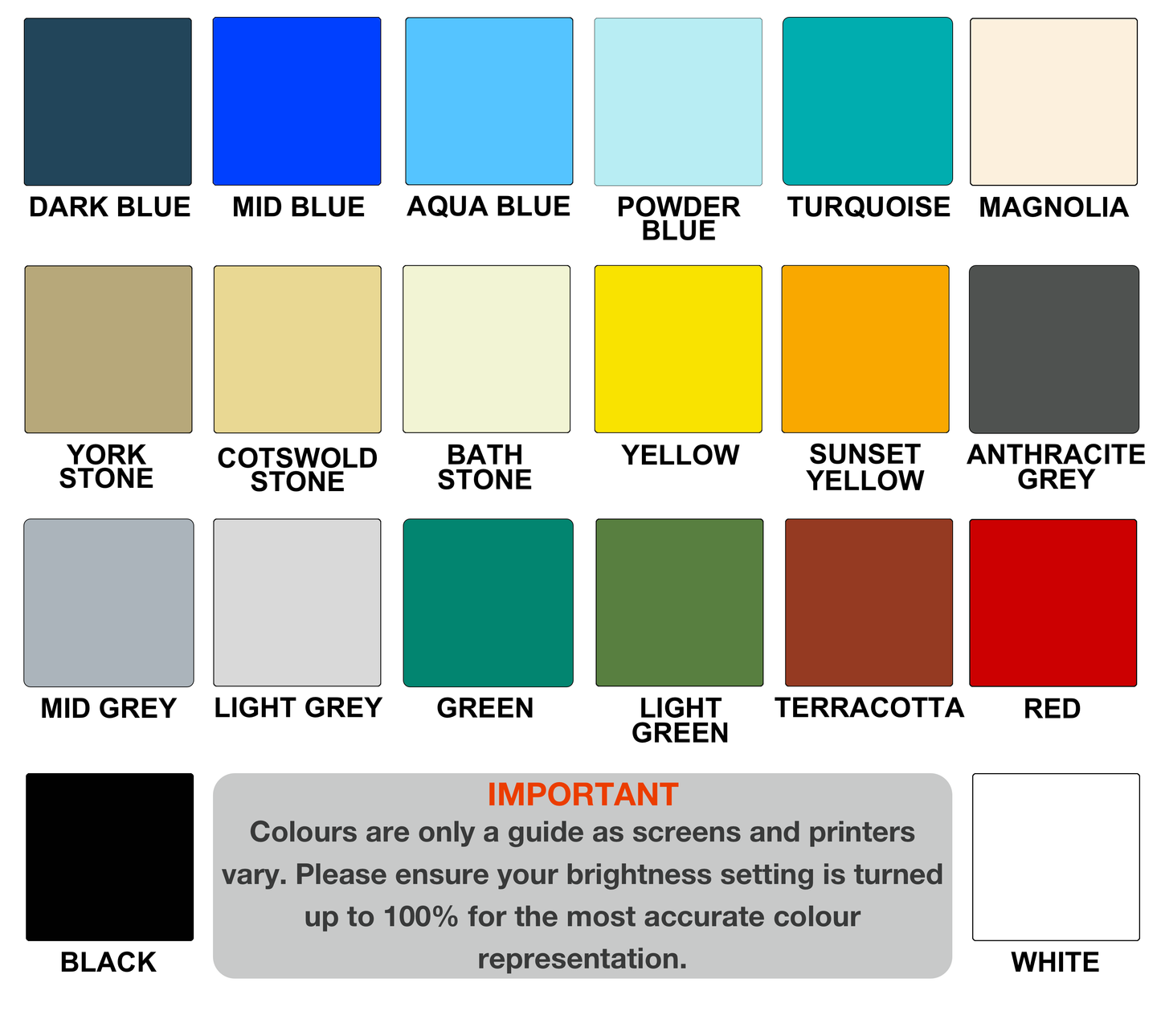

• Decorative finish

• Good water spot and blush resistance

3. USES

• Food/hygiene e.g. Abattoirs,/milking parlours

• Factory floors

• Car plants

• Hospitals

• Garages

• Metal Substrates

4. INSTRUCTIONS FOR USE

5.1. PREPARATION

THE PERFORMANCE OF THE COATING CAN BE SERIOUSLY IMPAIRED IF THE FOLLOWING INSTRUCTIONS ARE NOT STRICTLY ADHERED TO. IT IS CRUCIAL THAT THE SUBSTRATE IS SOUND.

Do not apply in temperatures below 10 °C/50 °F and ensure there is at least a 4 hour weather window. We do not recommend application late in the day, due to dropping temperatures and increased humidity.

Although Dairy Coat Ultra will overcoat most other finishes and paints, the best results are achieved when surfaces are clean and free of other finishes/coatings. If applying over an existing coating or to a non-porous surface, mechanically sand the area to create a key.

All surfaces should be dry. Particular attention should be made to degreasing surfaces before application. All voids and surface imperfections must be carefully filled.

Clean the surface you will be applying the Dairy Coat Ultra to. If there are any leaks, these should be repaired with Antel Waterstop or Antel Epoxy Putty before applying the Dairy Coat Ultra. If unsure, please contact us for technical advice.

The pot life is approximately 45 minutes. This is based on a temperature of 20 °C/68 °F. If you are applying the coating in higher temperatures, the pot life may be reduced. The material will become unworkable once outside of this pot life.

Once mixed, it is only possible to apply a single coat. Do not attempt to return to the mix to apply a second coat.

5.2. MIXING

For simplicity we would recommend using a separate pack of Dairy Coat Ultra for each coat, however if you would like to use one pack for both coats, you will need to accurately divide the A and B packs proportionately using digital scales.

1. Mix the A Pack thoroughly on a slow speed.

2. Mix the B Pack thoroughly on a slow speed.

3. Pour the contents of the B Pack into the larger A Pack.

4. Mix again thoroughly on a slow speed (ideally with a mixer paddle) for a minimum of three minutes, so that the two components are completely mixed.

5. Pour into at least one roller tray to maintain pot life.

6. Start application immediately.

5.3. APPLICATION STEPS

1. Apply the first coat by short pile roller or brush.

2. Wait 24 hours before applying the second coat. Reduced time between coats maybe possible, but it’s very important to seek technical advice from Antel before attempting this.

3. Within a maximum period of 48 hours, apply the second coat.

6. PACKAGING AND COVERAGE

Antel's Dairy-Coat Ultra is available in 5 Kg packs. Coverage is 15-20m2/5Kgs

7. CLEANING

Brushes and roller equipment should be cleaned with Antel's Standard Epoxy Cleaning Solvent.

8. STORAGE

Store in a dry, cool, and frost free place in their original containers.

9. TECHNICAL DATA

(20oC)

Pot life - 30 minutes

Application thickness - 200-225 µm per coat

Initial cure - 8 – 10 hours

Intercoat time - 24 hours

Pedestrian traffic - 24 hours

Heavy traffic - 36 hours

Full Cure - 7 days

Compressive Strength - 65 N/mm2

Flexural Strength - 26 N/mm2

Abrasion Resistance - 0.18 grams weight loss / CS-17 wheel 1000 cycles / 1 kg

Slip Resistance

Over a third of all major injuries reported each year are caused as a result of a slip or trip. Health and Safety Executive statistics suggest that there is one serious slip accident every 3 minutes.

Using the TRL Pendulum Slip/ Skid Resistance Tester in accordance with BS 7976-2, Slip/Skid Resistance Testing can be carried out to assess the floor surface slipperiness in workplace and public areas.

Facilities managers, local authorities and building owners are under obligation to ensure the floor or surface of the traffic route is not slippery so there is no risk of injury to any person. This is enforced by the "Workplace (Health, Safety and Welfare) Regulations 1992".

The UK HSE's preferred method for Slip assessment is based on a combination of two values:

1. Pendulum coefficient of friction (CoF) test resulting in a PTV rating.

2. Surface roughness value (Rz)

Surface Micro Roughness Assessment/Testing

Research has shown that measurement of the RZ parameter allows slipperiness to be predicted for a range of common materials. A roughness reading can be used as supporting evidence with the results of a pendulum test.

The pendulum test value (PTV) should be not less than 35 in situations where ease of cleaning is more critical than slip resistance and/or where all who use or are likely to use the floor will wear specially provided slip resistant boots or shoes. Pendulum test values in the wet of not less than 33 may be deemed acceptable.

Slip Resistance Guidelines

PTV Surface Roughness µm Potential for slip

0 to 24 ≤ 9 High

25 to 35 10 to 19 Moderate

≥ 36 ≥ 20 Low

Antel Dairy-Coat Ultra Results - based on application of 0.3 – 0.6mm Anti-Slip Aggregate

In accordance with BS 7976 Pt 1 -3

PTV (Dry) - 75

PTV (Wet) - 60

Surface roughness (Rz) - 92µm

Chemical Resistance

Sulphuric Acid - 30% - Excellent

Sodium Hydroxide - 25% - Excellent

Engine Oil - Excellent

Lactic Acid - 25% -Good

Ammonia Solution - 25% - Good

Citric Acid - 25% - Excellent

Petrol - Excellent

Sugar Solution - 40% - Excellent

Hydrochloric Acid - 30% - Excellent

Xylene - Excellent

White Spirit - Excellent

Skydrol - Excellent

Petrol - Excellent

Methanol - Moderate

Bleach - 10% -Excellent

Further technical information can be made available on request. Please contact the Antel Technical Department.

Need some expert advice?

Our knowledgeable support team is here for you! Whether you have questions about a specific product or need help choosing the right one, we're happy to assist.